Centrifugal Clutches and Brakes

How they work

The sprung tensioned flyweights rotate faster until they start to engage with the housing. This speed controlled engagement means they can function as an automatic clutch or brake to control descent rate.

Combidrive Ltd. is the sole UK agent for the German company Robert Scheuffele (Trademark ‘SUCO’ Centrifugal clutches from the SUCO are often found in the following machinery

- Plate Compactor

- Vibrating beams

- Vibrating rollers

- Rotary levellers

- Rammers

- Power floats

- Wood chippers

- Disc cutters

- Rotary sweepers

- Turf working machinery

- Motorised barrows

- Small vehicles

EXAMPLE

Centrifugal clutch type 1

Maximum capacity: 25HP* @ 3000

RPM with integral twin pulley

108 mm diameter for SPA belts

Bore size: 25.4 mm (1”) †

Depth: 72 mm double bearing support

EXAMPLE

Centrifugal clutch type 2

Maximum capacity: 50HP* at 3000 RPM

without pulley but a 85 mm fixed diameter

housing diameter 145 mm

Bore size: 25.4 mm (1”) †

Depth: 70 mm single bearing support

CENTRIFUGAL CLUTCH/ BRAKE –

PRINCIPLE OF OPERATION

Friction lined flyweights are held in position by springs which can be changed to adjust the speed at which the clutch/brake begins to engage.

As the hub accelerates, centrifugal force acting on the flyweights, overcomes the spring tension, allowing the friction lined flyweights to bear on the housing and so impart drive (when acting as a clutch) or braking effect (when acting as a brake) Watch the housing accelerate as the clutch engages. IT’S ALL GRIPPING STUFF!!

CENTRIFUGAL CLUTCH CARE

FROM COMBIDRIVE

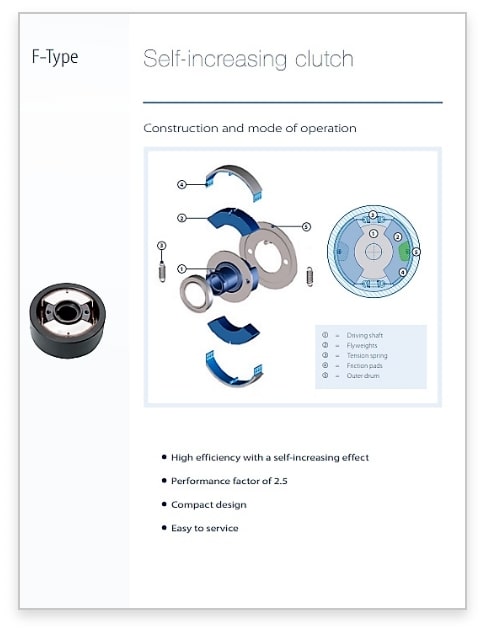

F-Type

The compact design and self-increasing effect allow this clutch to transmit remarkably high torques while needing very little space, resulting in performance factors of ca. 2.5.

Because the tension springs are easily accessible and the linings removable. the parts subject to wear are easy to replace. Because the linings are not secured to the flyweights some noise is possible in service, but normally not sufficient to cause a nuisance.

Self increasing effect: the profiled hub has a special form which causes a wedging effect between the profile and the flyweights when torque is applied to the clutch. This results in an additional force on the linings and allows a higher torque to be transmitted.

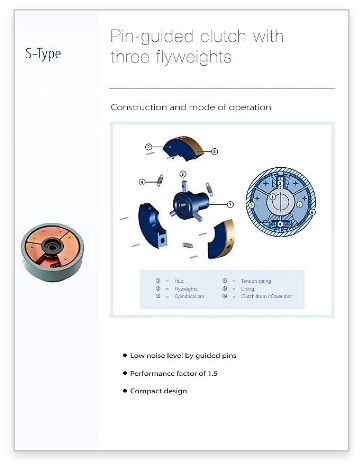

S-Type

In contrast to F-Type clutches, the linings of pin-guided clutches are permanently bonded to the flyweights instead of being mounted on loose carriers. The guide pins of W-Type clutches provide accurate guidance for the flyweights, which ensures quiet operation of the clutch.

For this type of clutch, the performance factor for torque transmission is ca 1.5.

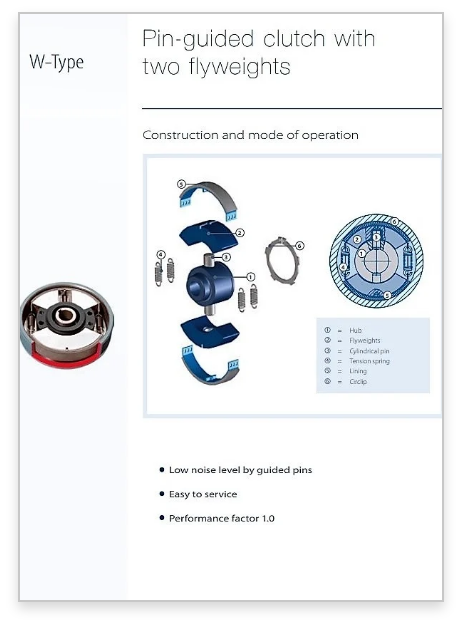

W-Type

The W-Type combines the advantages of F- Type and S-Type clutches. Because the tension springs are easily accessible and the linings removable, the parts subject to wear are easy to replace.

As with the S-Type, the guide pins provide accurate guidance for the flyweights, which ensures quiet operation of the clutch. For this type of clutch, the performance factor for torque transmission is 1.0.

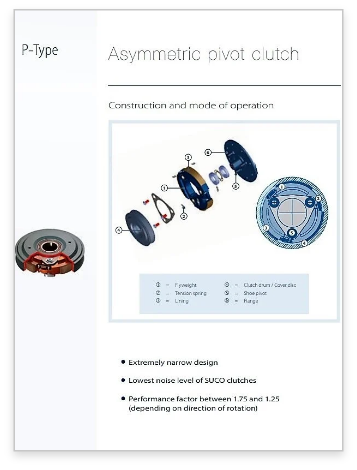

P-Type

P-Type clutches are extremely narrow.

In addition, the asymmetric pivot clutch is the quietest-running clutch in the SUCO product range. for this type of clutch, the performance factor for torque transmission is ca. 1.75 or ca. 1.25 depending on the direction of rotation.

Some popular applications include:

- Plate Compactors

- Vibrating beams/rollers

- Rotary Leveller

- Power Floats

- Refrigerated Transport

- Pump Sets

- Band saws

- Elevators

- Winches

- Standby Drives

- Centrifuges

- Compressors

- Go Karts

- Dual System Drives

- Wood chippers

- Lifting equipment with overspeed-clutch control (auto braking)

- Motorised barrows

- Rotary sweepers

- Small vehicles

- Mixing machines

AUTOMATIC CENTRIFUGAL BRAKING MADE EASY

Winch systems may need protection when lowering a load to prevent the possibility of overspeeding and consequential damage or injury. Typical transmissions comprise a motor fitted with failsafe brake and hand release, connected to the geared winch system. However such control does not protect against overspeeding during lowering a load or when manually controlling descent in the event of power failure.

A Suco modular brake can easily be fitted between a standard IEC motor and gearbox, as an original specification or retrofitted to an existing system.Respective flange spigots ensure any possibility of angular and/or radial misalignment of the brake hub is eliminated.

Typically, automatic braking would commence at say 1650 RPM when running with a 1400 RPM motor.

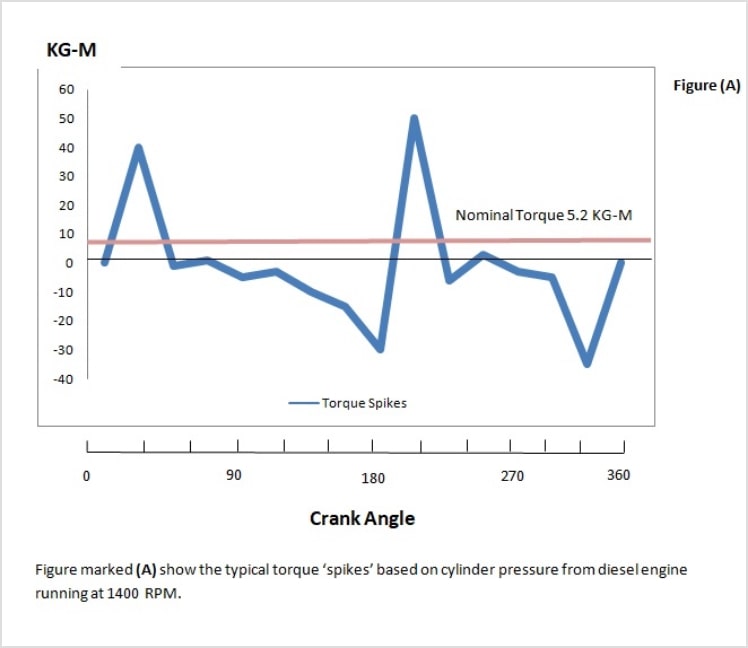

CENTRIFUGAL CLUTCH DESIGNED TO DEAL WITH TORSIONAL VIBRATIONS

Most of us will know when we are alongside a diesel truck when everything is rattling as we wait for the lights to change.

Very high cylinder pressure with each power stroke from every piston can produce torque “spikes” as high as 7 times the nominal torque from the engine.

Such ‘roughness’ from the diesel engine compared to a petrol engine where torsional vibrations are of a much lower level, must be absorbed by the subsequent transmission components.

The Suco P type clutch embodies rubber bushes in the 3 asymmetric shoes, this design enables the clutch to absorb such torsional vibration to give quiet running and long service life.

Centrifugal clutch type 1

Maximum capacity: 25HP* @ 3000 RPM with integral twin pulley

108 mm diameter for SPA belts

Bore size: 25.4 mm (1”) †

Depth: 72 mm double bearing support

Centrifugal clutch type 2

Maximum capacity: 25HP* @ 3000 RPM without pulley but fixing 80 mm diameter

Bore size: 25.4 mm (1”) †

Depth: 72 mm double bearing support

Centrifugal clutch type 3

Maximum capacity: 25HP* @ 3000 RPM with integral pulley

132 mm diameter for SPB belt

Bore size: 25.4 mm (1”) †

Depth: 52 mm single bearing support

Centrifugal clutch type 4

Maximum capacity: 25HP* @ 3000 RPM with adaptor plate for fitting sprocket (e.g. go carts)

Depth: 74 mm single bearing support

Centrifugal clutch type 5

Maximum capacity: 8HP* @ 3000 RPM with integral 125 mm

diameter pulley for SPA belt

Bore size: 19.05 mm (3/4) †

Depth: 41 mm single bearing support

Centrifugal clutch type 6

Maximum capacity: 50HP* @ 3000 RPM without pulley but a 85 mm fixed diameter housing diameter 145 mm

Bore size: 25.4 mm (1”) †

Depth: 70 mm double bearing support

*Maximum HP capacity is a guide, correct selection depends on driving speed and duty.

Also belt capacity needs to be taken into account.

For more information visit the Suco website