News

16 December 2025

RELIABILITY FROM RUHRGETRIEBE

13 October 2025

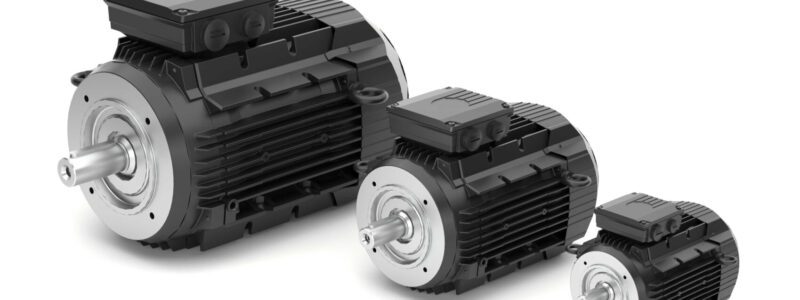

Electric Motors from the Uk’s largest stockist – TEC

13 March 2025

ONE WAY FREEWHEELS AND BACKSTOPS FROM STIEBER

13 March 2025

50 YEARS IN BUSINESS!

5 March 2025

CENTRIFUGAL CLUTCHES AND BRAKES FROM SUCO

17 February 2025

ROLLER OR SPRAG FREEWHEELS FROM STIEBER

30 January 2025

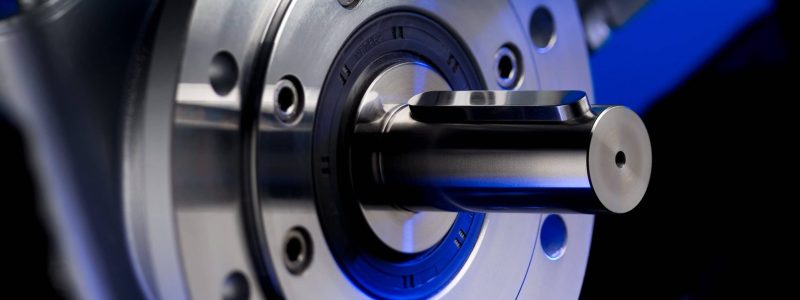

COMBINED BEARING FREEWHEEL PRODUCT FROM STIEBER

31 January 2025

STIEBER OVERRUN CLUTCH IN WORLD RECORD CAR

22 January 2025

LAFERT & RUHRGETRIEBE: OUR EXPANDED SERVICE OFFERING.

27 November 2024